Industry information

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum veneer: a shining pearl in architecture, both environmentally friendly and fashionable

- The Art and Science Behind Aluminum Ceiling

- Aluminum honeycomb panel: the secret power behind lightness

- Aluminum curtain wall, the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum ceiling, creating a new trend of fashionable home decor

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum ceiling: the new darling of modern architecture, with infinite charm!

- Aluminum veneer new trend, new chapter in architectural aesthetics

Frequently asked questions

- What is the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Material selection and construction control for customized aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 10, 2025 23:50:12

- Click:0

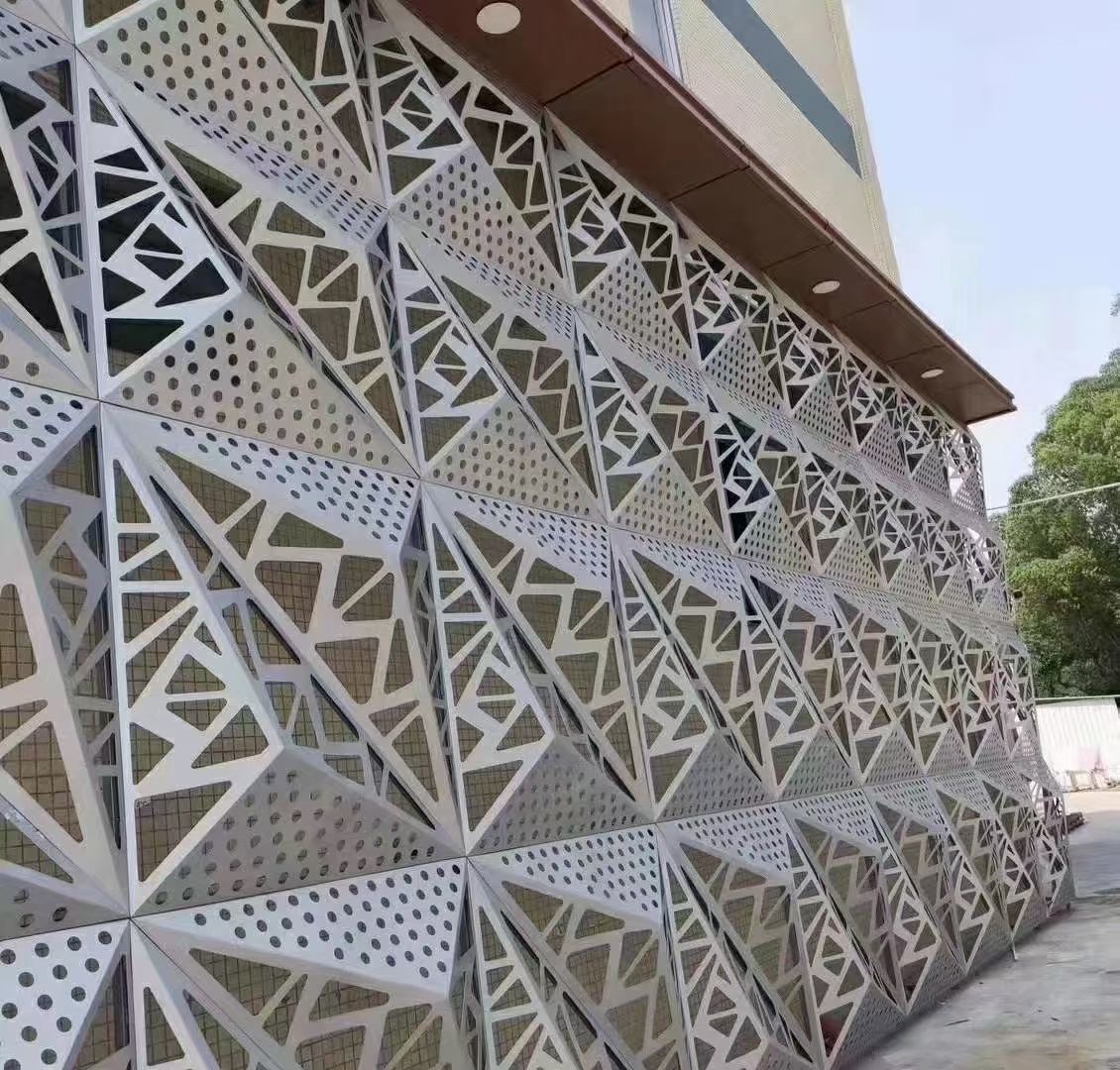

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, corrosion resistance, and easy processing, and has been widely used in the field of building decoration. The material selection and construction control of customized aluminum veneer are also important issues that enterprises must face. Below, we will provide a detailed introduction to the selection of customized materials and construction control for aluminum veneer.

1、 Material selection

1. Selection of raw materials

Before customizing aluminum veneer, it is necessary to fully prepare and screen the required raw materials to ensure the quality and stability of the aluminum veneer. This includes aluminum alloy sheets, surface treatment agents, sealants, etc.

2. Performance requirements for materials

When selecting materials, attention should be paid to their performance requirements, including strength, hardness, corrosion resistance, processability, etc. At the same time, suitable materials need to be selected based on specific needs and design requirements.

3. Environmental friendliness and healthiness of materials

When selecting materials, it is also necessary to consider their environmental friendliness and health, and avoid using materials that are harmful to human health or contain harmful substances. At the same time, it is necessary to comply with relevant national standards and regulations.

2、 Construction control

1. Construction control during the design phase

During the design phase, construction control is required for the design and production of aluminum veneer molds, including dimensional accuracy, surface smoothness, material selection, etc. At the same time, it is necessary to record and provide feedback on the construction process to provide a basis for subsequent improvements.

2. Construction control during the production phase

During the production phase, construction control is required for the production process of aluminum veneer, including the use of raw materials, maintenance of production equipment, and control of the production environment. At the same time, it is necessary to record and provide feedback on the production process to provide a basis for subsequent improvements.

3. Construction control during the installation phase

During the installation phase, construction control is required for the installation process of aluminum veneer, including installation methods, fixing point settings, and selection of connectors. At the same time, it is necessary to record and provide feedback on the installation process to provide a basis for subsequent improvements.

4. Quality inspection and testing

After installation, it is necessary to conduct quality inspection and testing on the aluminum veneer to ensure that it meets the design requirements and national standards. At the same time, it is necessary to package and transport the product to ensure its safety and integrity.

3、 Conclusion and Prospect

Through the detailed introduction of material selection and construction control above, it can be seen that the material selection and construction control of customized aluminum veneer are important issues that enterprises must face. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to product quality and service level to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen comparative research with other materials to provide consumers with more comprehensive and objective selection criteria. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ