Frequently asked questions

Company News

- Aluminum curtain wall: not only the exterior of the building, but also the integration of art and technology

- Aluminum ceiling: the new darling of modern home decoration

- Aluminum veneer: the beauty of architecture, the soul of details

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the 'hidden hero' of modern architecture

Industry dynamics

- Customize aluminum veneer to create a personalized home fashion trend

- Aluminum veneer customization, creating a new trend of personalized space

- Expansion of sales channels and market promotion for aluminum veneer

- Aluminum ceiling, revealing the fashionable choice of modern home!

- The Charm of Aluminum Honeycomb Panel: The Perfect Fusion of Lightness and Sturdiness

Frequently asked questions

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What will be the future development trend of aluminum veneer?

- What is the future development trend of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What issues should be noted in the production process of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 04:25:48

- Click:0

What issues should be noted in the production process of aluminum veneer?

In the production process of aluminum veneer, in order to ensure the quality and safety of the product, it is necessary to pay attention to the following four aspects:

1、 Material procurement

1. Raw material selection: Choose suitable aluminum alloy materials to ensure excellent oxidation resistance, corrosion resistance, and wear resistance. At the same time, the cost and reliability of materials need to be considered.

2. Supplier selection: Look for reputable suppliers, conduct qualification audits and quality assessments to ensure that the materials provided meet relevant standards and requirements.

3. Quality control: Strictly inspect each batch of incoming materials, including appearance, size, chemical composition, and other aspects, to ensure stable quality.

2、 Processing technology

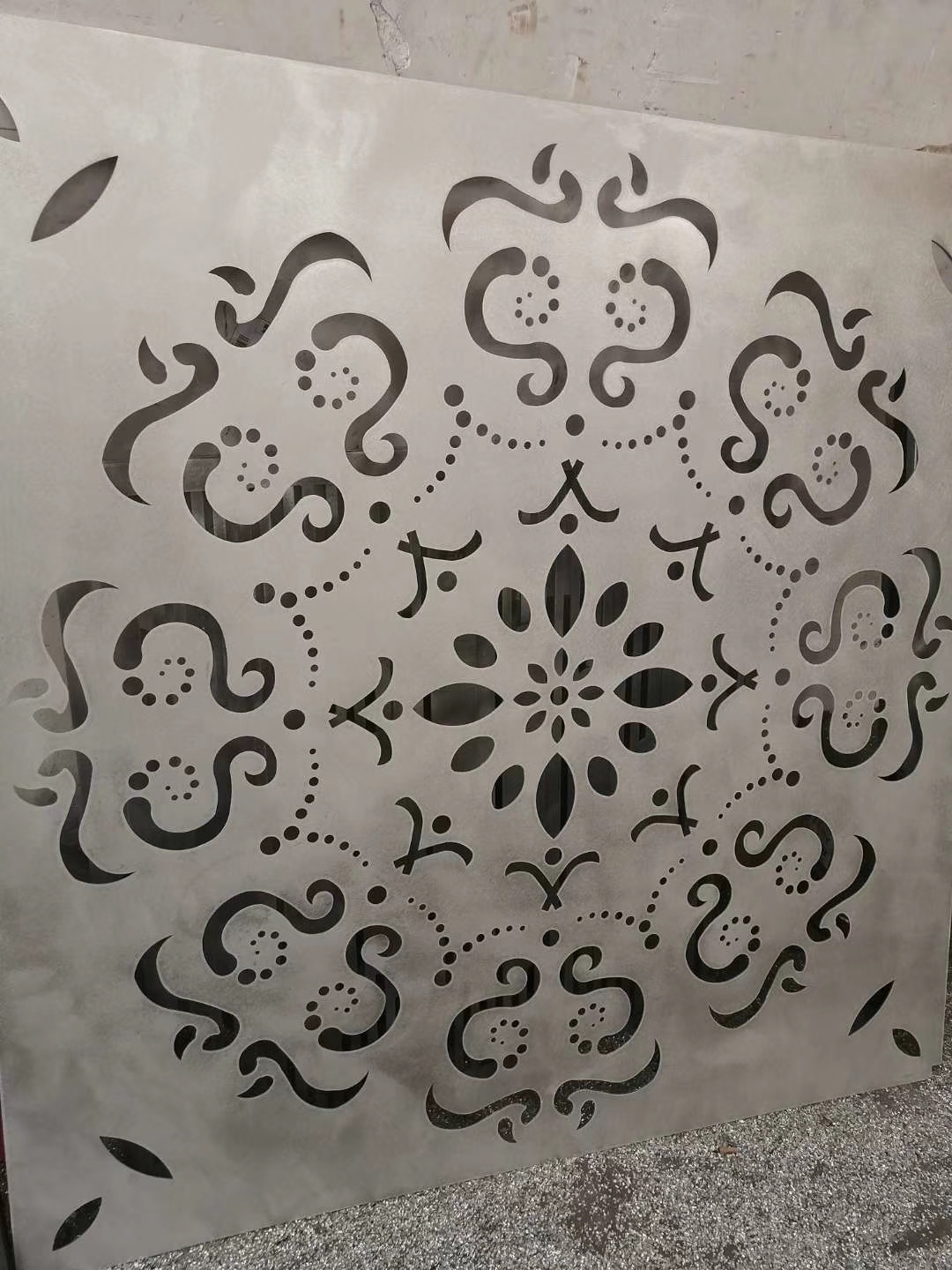

1. Mold design: Based on product requirements and customer needs, design a suitable mold structure to ensure the accuracy of product shape and size.

2. Processing flow: Develop detailed processing technology flow, including cutting, stamping, bending and other links, to ensure the processing quality and efficiency of each link.

3. Equipment maintenance: Regularly inspect and maintain processing equipment to ensure normal operation and avoid production delays and quality issues caused by equipment failures.

3、 Surface treatment

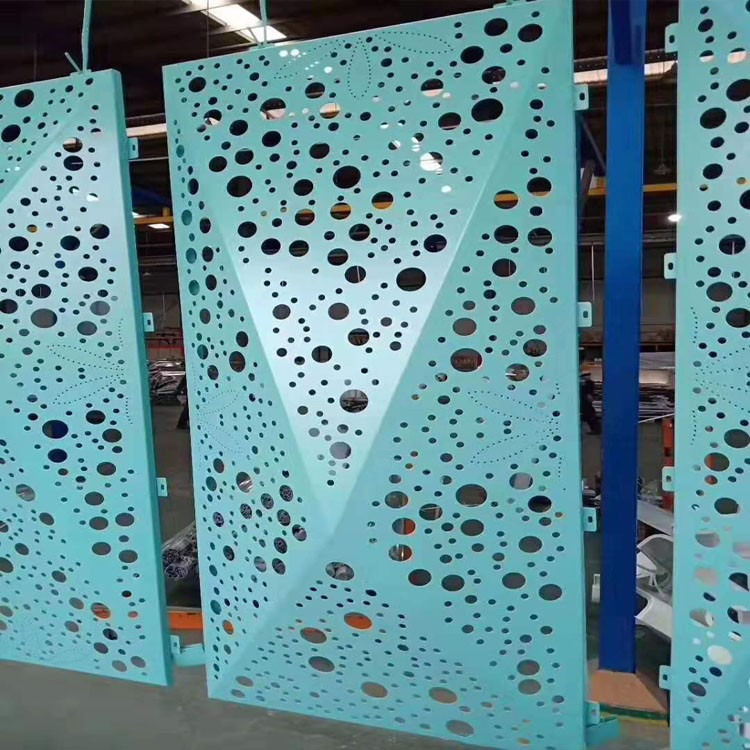

1. Oil and oxygen removal: Before processing aluminum veneer, surface oil and oxygen removal treatment is carried out to ensure the stability of the coating effect.

2. Coating process: Choose the appropriate type of coating and coating process to ensure the adhesion, weather resistance, and color durability of the coating.

3. Spray control: Strictly control the spray process, including spray thickness, uniformity, and drying time, to ensure coating quality.

4、 Quality inspection

1. Appearance inspection: Conduct a visual inspection of the completed aluminum veneer, including surface flatness, color consistency, scratches, and other defects.

2. Dimensional measurement: Use precision measuring tools to check the dimensions of aluminum veneer to ensure compliance with design requirements and customer needs.

3. Functional testing: Testing the functionality of aluminum veneer, such as strength, weather resistance, and fire resistance, to ensure the reliability and qualification of the product.

Summary:

In the production process of aluminum veneer, material procurement, processing technology, surface treatment, and quality inspection are four aspects that require special attention. By selecting materials reasonably, optimizing processing techniques, strictly controlling surface treatment, and conducting comprehensive quality inspections, the quality and safety of aluminum veneer products can be guaranteed, meeting the needs and expectations of customers.

Customer service QQ

Customer service QQ