Frequently asked questions

Company News

- New trend of aluminum ceiling: simple but not simple

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating a new proposition for personalized space

- The secret of aluminum honeycomb panel: hardcore technology behind its lightweight design

- Customized aluminum veneer, a new choice for personalized space

Industry dynamics

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Honeycomb aluminum plate: a secret weapon as light as a feather and as solid as a rock

- The production process and technical characteristics of aluminum veneer

- Honeycomb aluminum plate: the secret power behind lightness

Frequently asked questions

- What is the market demand for aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

- What are the main uses of aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the difference between aluminum veneer and aluminum-plastic panel?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 9, 2025 18:54:23

- Click:0

What is the difference between aluminum veneer and aluminum-plastic panel?

Abstract: This article will elaborate on the differences between aluminum veneer and aluminum-plastic panel from four aspects, including material properties, manufacturing processes, appearance effects, and application fields. By comparing and analyzing, help readers comprehensively understand the characteristics and advantages and disadvantages of these two materials.

1、 Material properties

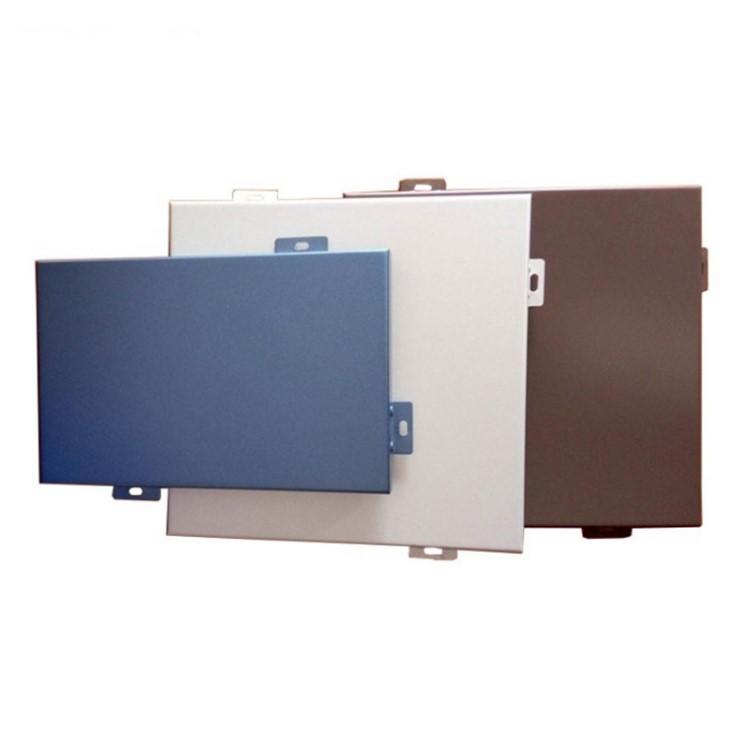

1. Aluminum veneer: Aluminum veneer is processed from high-purity aluminum material and has high strength, corrosion resistance, and oxidation resistance. It is usually made of single-layer aluminum plate, lightweight and sturdy, suitable for outdoor environments.

2. Aluminum plastic panel: Aluminum plastic panel consists of a plastic core material sandwiched between two thin aluminum plates, with an outer layer of aluminum plate and an inner layer of plastic. Aluminum plastic panels are lighter than aluminum veneers, but have lower strength. Meanwhile, the presence of plastic core material enhances its fire resistance performance.

2、 Manufacturing process

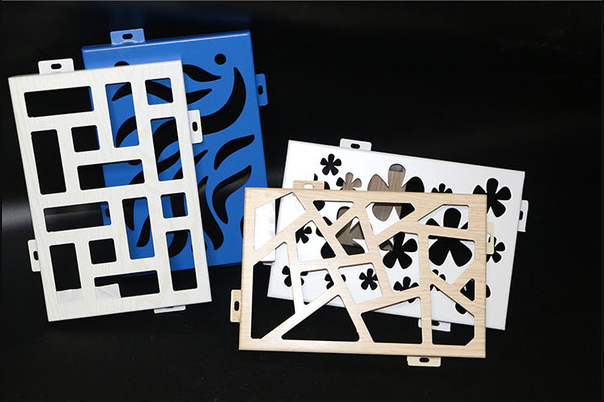

1. Aluminum veneer: The production of aluminum veneer generally adopts processes such as cutting, bending, and welding, which require multiple processes to complete the finished product. The production process is relatively complicated, but various shapes and curve effects can be created according to the needs.

2. Aluminum plastic panel: The production of aluminum plastic panel is relatively simple, mainly using extrusion molding process and adhesive to fix two layers of aluminum plate and plastic core material. This process is faster and more efficient, suitable for large-scale production and installation.

3、 Appearance effect

1. Aluminum veneer: The surface of aluminum veneer is treated by spraying, oxidation, etc., which can present a rich and diverse color and texture effect. At the same time, it can also achieve personalized appearance design through processing methods such as bending and punching.

2. Aluminum plastic panel: The appearance of aluminum plastic panel is relatively simple, usually presented with a uniform color and a flat surface. It is impossible to achieve diversified appearance treatment and creative design like aluminum veneer.

4、 Application Fields

1. Aluminum veneer: Due to its excellent corrosion resistance and weather resistance, aluminum veneer is widely used in fields such as exterior wall decoration, roofs, ceilings, etc. Meanwhile, it can also be used for decoration and partition in public places such as stations and airports.

2. Aluminum plastic panel: Due to its lightweight and easy processing and installation, aluminum plastic panel is mainly used in indoor decoration, advertising billboards, commercial storefronts and other fields. Its fire resistance also makes aluminum-plastic panels have certain application value in building curtain walls and insulation materials.

5、 Summary:

Through the above comparative analysis, we can see that there are some significant differences between aluminum veneer and aluminum-plastic panel in material properties, manufacturing processes, appearance effects, and application fields. Aluminum veneer is suitable for architectural decoration with high appearance requirements, while aluminum-plastic panels are more suitable for indoor decoration and commercial advertising applications. Choosing suitable materials based on actual needs can achieve better decorative effects and user experience.

- previous page:What are the main uses of aluminum veneer?

- Next page: No more

Customer service QQ

Customer service QQ