Industry information

Company News

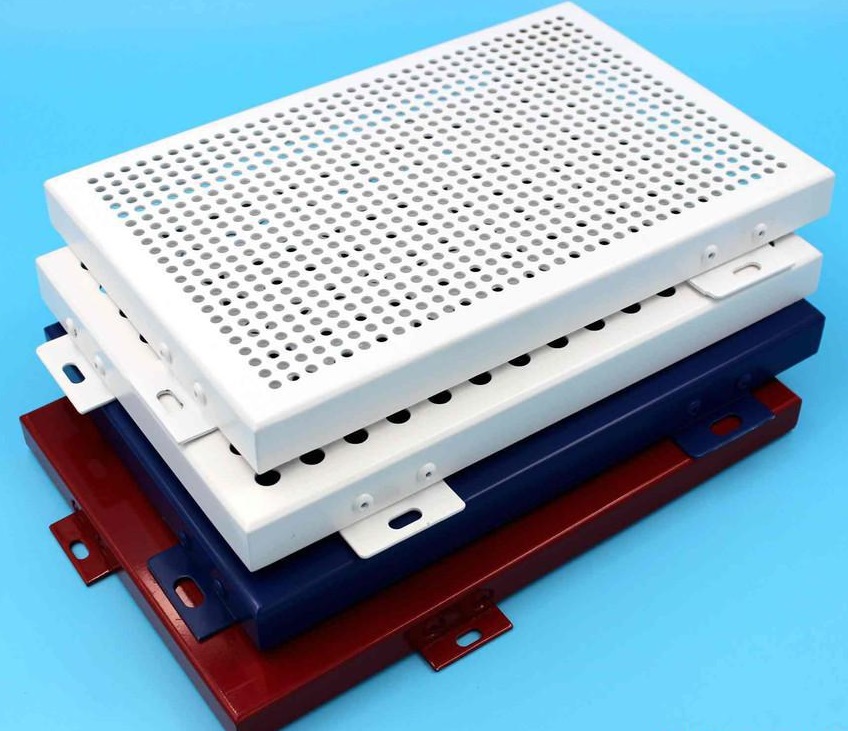

- Aluminum veneer: a modern interpretation of industrial aesthetics

- The Beauty of Aluminum Curtain: The Fashionable Coat of Modern Architecture

- Aluminum veneer: the beauty of architecture, the soul of details

- The Charm of Aluminum Honeycomb Panel: The Perfect Fusion of Lightness and Sturdiness

- Aluminum veneer customization, creating the art of personalized space

Industry dynamics

- The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Aluminum Curtain Landscape: Not Just the Beauty of Architecture

- Design style and decorative effect of stone patterned aluminum veneer for exterior walls

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- What is the market demand for aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What will be the future development trend of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret weapon of lightweight structure

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-25 22:12:27

- Click:0

Dear friends from the construction and industrial industries, today let's talk about a super cool material - honeycomb aluminum plate. This name sounds a bit mysterious, doesn't it? Don't worry, let's talk slowly.

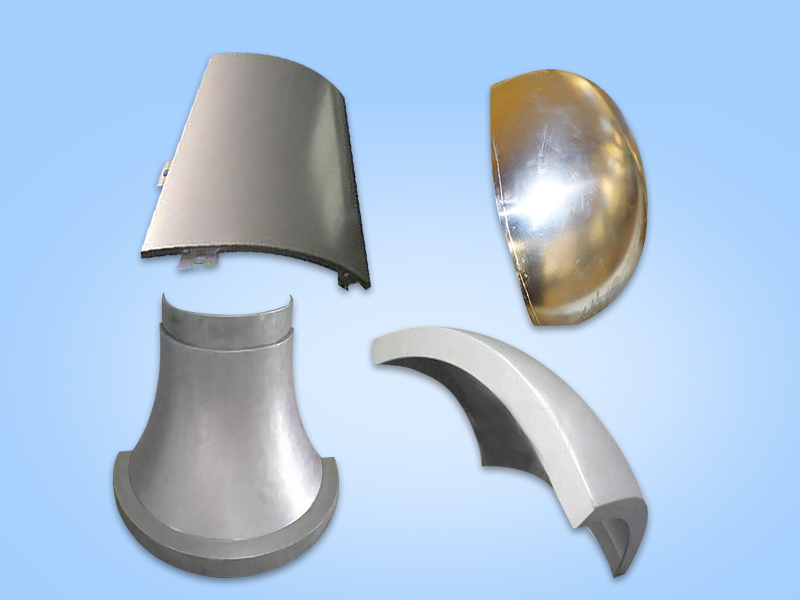

Honeycomb aluminum plate, sounding like a high-tech product moved out of an ant's house, is actually a lightweight and high-strength material. Let's first imagine a honeycomb that is both lightweight and sturdy. How is this achieved? Honeycomb aluminum plate is made from aluminum metal, drawing inspiration from this structure. Its surface looks honeycomb shaped, hence its name.

I first came into contact with honeycomb aluminum panels at a friend's factory, where he was busy making some industrial parts using this material that day. At that time, I thought to myself, this thing looks ordinary, why is it so popular? Later on, I realized that there were many mysteries involved.

Honeycomb aluminum plate is lightweight. Imagine a building, how much material and labor can you save if you can build it with lighter materials? The density of honeycomb aluminum plate is only about 1/3 of aluminum, but its strength is similar to aluminum, making it a convenient and effortless helper.

It dissipates heat quickly. Summer is here, and we all know that metal products are prone to heat, but honeycomb aluminum panels are different. They dissipate heat quickly, so buildings made with this material will be cooler in summer.

Furthermore, honeycomb aluminum panels have good sound insulation effects. Have you ever noticed the sound insulation materials used in cars? Many of them are honeycomb aluminum plates. Because it can reduce noise while maintaining structural stability.

Honeycomb aluminum plate also has good corrosion resistance, is not afraid of wind and rain, and has a long service life. Whether in construction, aviation, automobiles, or electronic devices, honeycomb aluminum panels can show off their skills.

Speaking of which, I would like to share a little story. Once, while interning at a design institute, an engineer was designing a complex structure using honeycomb aluminum panels. He told me that this material can make the structure lighter and can be designed to be more complex. I was thinking at that time, this material is simply a masterpiece in the design world!

Every material has its limitations. Honeycomb aluminum sheet also has its weaknesses, such as high cost and difficult processing. With the advancement of technology, these are no longer problems. Many factories have started researching how to reduce the cost of honeycomb aluminum panels and improve processing efficiency.

The application of honeycomb aluminum plates is becoming increasingly widespread. Many of the drones we commonly see have bodies made of honeycomb aluminum panels. Also, some high-end smartphones may use honeycomb aluminum panels for their casings.

Where will honeycomb aluminum panels go in the future? I think that with the continuous development of technology, the application range of honeycomb aluminum panels will become increasingly wide, and it may become the mainstream of lightweight and high-strength materials in the future.

I want to say that although honeycomb aluminum panels are good, we need to approach them rationally. Any material has its applicable scenarios, and we need to choose the appropriate material based on specific needs. Just like the honeycomb aluminum plate we discussed today, although it has many advantages, it is not omnipotent.

Honeycomb aluminum plate is an excellent material that has a wide range of applications in many fields. Understand it, master it, and future architecture and industry may undergo earth shattering changes due to its existence. Let's look forward to more surprises from honeycomb aluminum panels together!

Customer service QQ

Customer service QQ