Corporate News

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- The 'castle in the air' of aluminum honeycomb panels: light as a feather, sturdy as a rock!

- The secret of aluminum honeycomb panel: the story behind its lightweight structure

- New trend of aluminum ceiling: lightweight and beautiful, fashionable choice

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock

Industry dynamics

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum veneer: a low-key "beauty artist" in the construction industry

- Honeycomb aluminum plate: the secret weapon of the lightweight era

- Aluminum curtain wall: the new darling of modern architecture

- Aluminum veneer: the "invisible armor" of modern architecture

Frequently asked questions

- What are the main uses of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Improvement of production efficiency and quality control of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 10, 2025 17:31:56

- Click:0

Improvement of production efficiency and quality control of aluminum veneer

Abstract: This article mainly discusses how to improve the production efficiency of aluminum veneer and strengthen quality control, including material selection, process optimization, equipment updates, and quality monitoring, and cites relevant research and viewpoints.

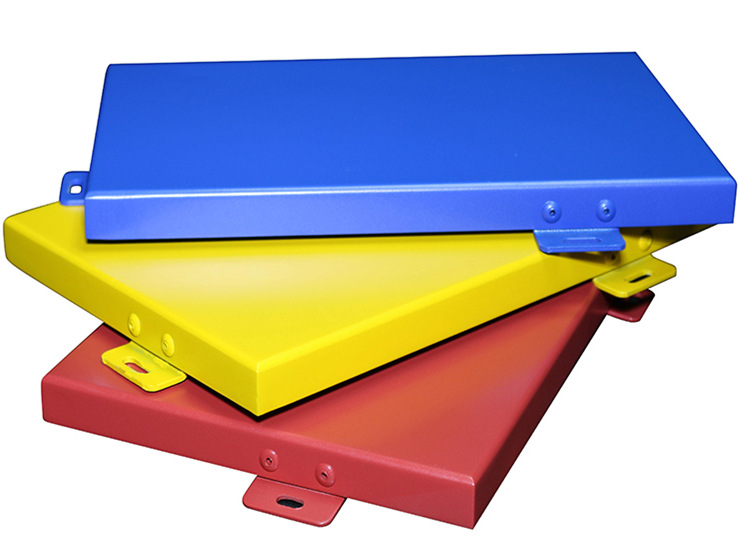

1、 Optimization of material selection

1. Reasonable selection of aluminum material models: Choose the appropriate aluminum material model according to different purposes and requirements to improve the strength and corrosion resistance of the material.

2. Optimize coating agent selection: Choose high-quality and environmentally friendly coating agents to increase the weather resistance and corrosion resistance of aluminum veneer, and reduce pollution and waste during the coating process.

3. Optimizing aluminum thickness: By precise calculation and experimental verification, the thickness of aluminum veneer is reasonably controlled, which not only meets the strength requirements but also improves production efficiency.

2、 Process optimization

1. Automated production line: Introducing advanced automation equipment to achieve unmanned operation and automated control, thereby improving production efficiency and quality stability.

2. Process parameter optimization: By analyzing and optimizing each process step, determine the optimal process parameters to maximize production efficiency and product quality.

3. Process improvement: Based on the actual situation, adjust and improve the production process to reduce waste and defects in the production process, and improve overall production efficiency.

3、 Equipment updates and maintenance

1. Introducing new equipment: Regularly updating production equipment, adopting more advanced equipment and technology, improving production efficiency and product quality.

2. Equipment maintenance: According to the established maintenance plan, regularly inspect and maintain production equipment to ensure its normal operation and stability.

3. Equipment monitoring and data analysis: By real-time monitoring of equipment operation and collecting data, problems can be identified in a timely manner, and data analysis methods can be used for fault warning and optimization improvement.

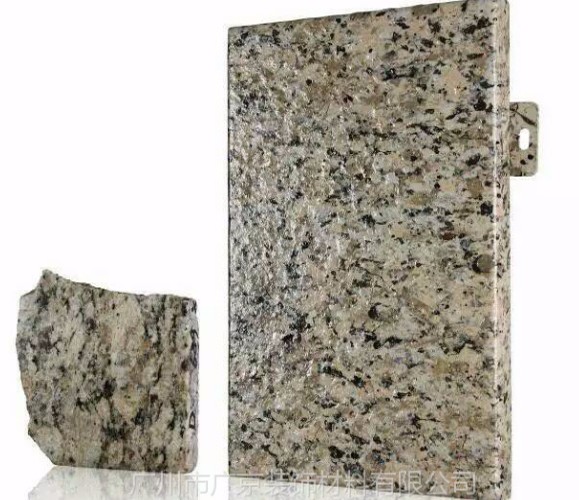

4、 Quality monitoring and control

1. Raw material inspection: Conduct strict quality checks on the purchased aluminum materials and coating agents to ensure that the raw materials meet the standard requirements.

2. Production process monitoring: By monitoring key process parameters and product quality indicators, real-time control and adjustment of the production process are carried out to ensure that the product meets the specified quality standards.

3. Finished product inspection: Conduct comprehensive finished product inspection on aluminum veneer, including appearance quality, dimensional accuracy, functionality, etc., to ensure that the product meets customer requirements.

5、 Summary:

By optimizing material selection, optimizing processes, updating and maintaining equipment, and monitoring and controlling quality, the production efficiency of aluminum veneer can be effectively improved, while strengthening quality control to ensure product stability and excellent quality. Future research and practice should further explore new process technologies and methods to adapt to the constantly changing market demands.

Customer service QQ

Customer service QQ