Industry information

Company News

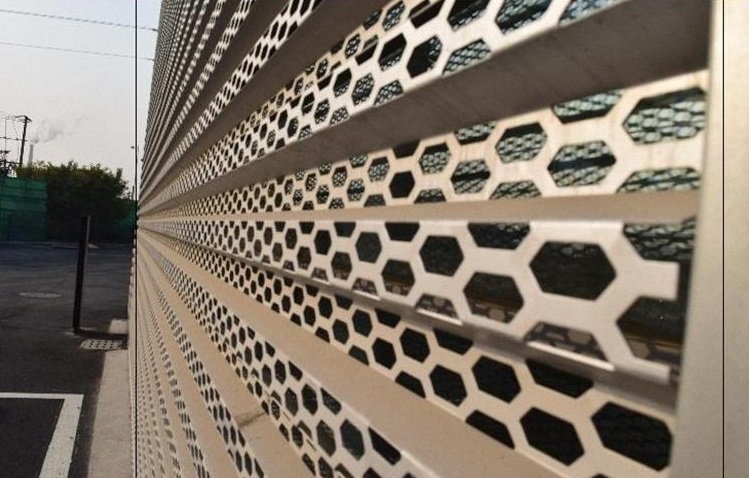

- Aluminum curtain wall: not just an exterior wall, but also a fusion of art and technology

- The wonderful world of aluminum honeycomb panels: the secret of lightweight and sturdy

- Aluminum ceiling: the beauty of lightness, the new darling of architecture

- Aluminum veneer, the fashionable choice in architecture!

- Aluminum ceiling: the fashionable choice of modern architecture, revealing its charm!

Industry dynamics

- Aluminum Curtain Wall: The Bright Wing in Modern Architecture

- Aluminum veneer: creating a new fashionable "metal skin" for modern architecture

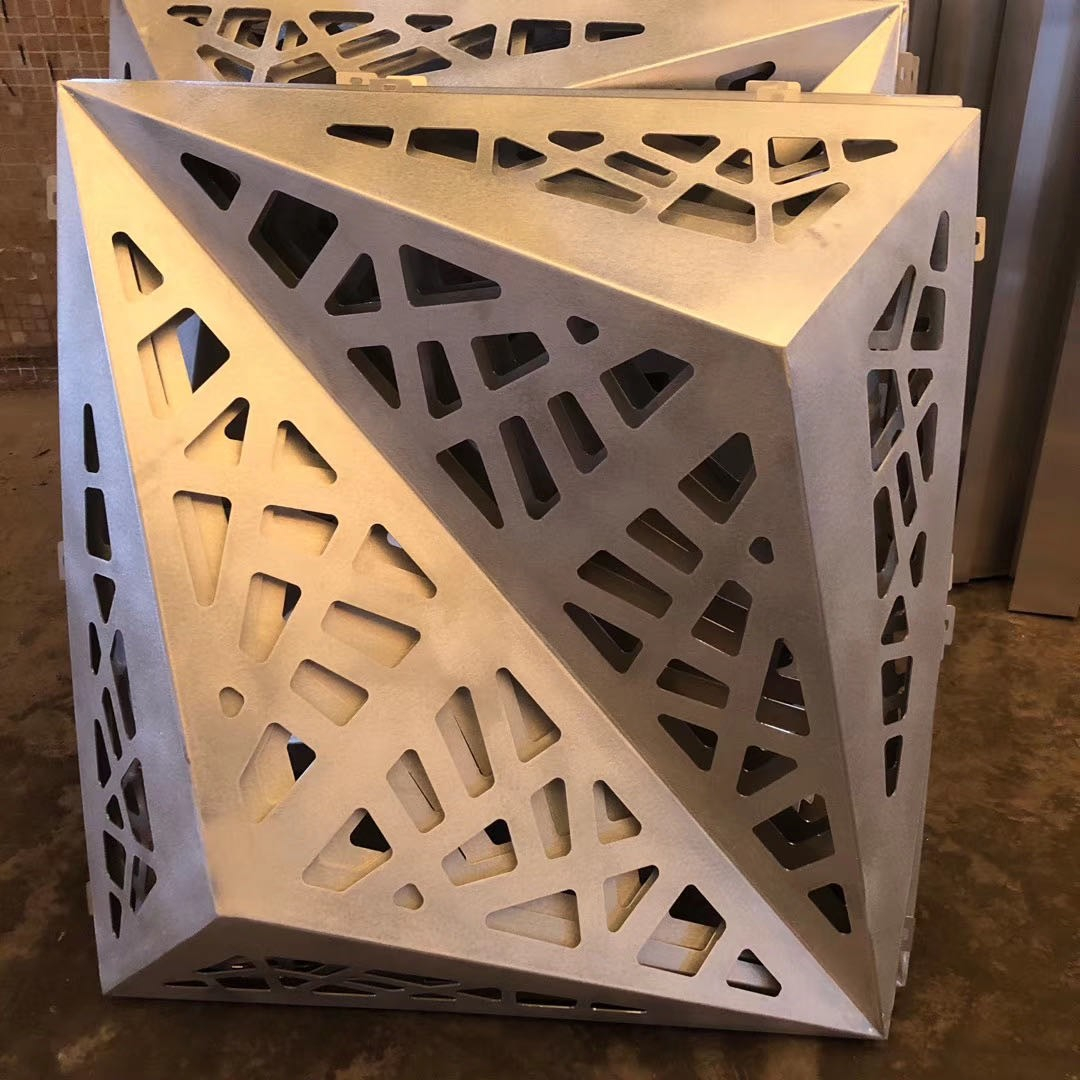

- Fine crafted 2.5mm carved aluminum veneer

- Honeycomb aluminum plate: the secret behind lightweight "aluminum"

- Aluminum veneer customization, creating a new proposition for personalized space

Frequently asked questions

- What are the main uses of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the market demand for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Seismic performance test of 1.5mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 21, 2025 00:12:19

- Click:0

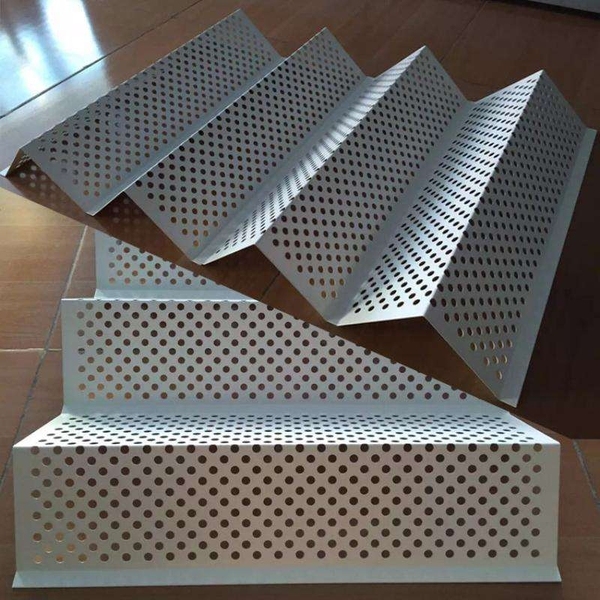

1.5mm aluminum veneer is a very common building material, and its seismic performance is one of the important factors to ensure building safety. This article will provide a detailed introduction to the seismic performance testing of 1.5mm aluminum veneer.

Preparation work is required before testing, including measurement, design, and scheme development. In terms of measurement, it is necessary to accurately measure the structural dimensions of the building and the dimensions of the aluminum veneer to ensure that the selected materials meet the actual needs. In terms of design, it is necessary to make reasonable designs and choices based on specific architectural styles and decorative effects. In terms of scheme formulation, it is necessary to consider factors such as the installation method and fixing method of aluminum veneer to ensure that the quality and effect of installation and construction meet one's own requirements and standards.

During the testing process, professional testing equipment and methods are required for inspection. The commonly used testing methods include seismic wave tests, vibration tests, etc. These tests can provide a comprehensive and systematic evaluation of the seismic performance of aluminum veneers, in order to determine whether they comply with building codes and safety requirements. During the testing process, attention should be paid to the accuracy and stability of the testing equipment, as well as factors such as the selection and setting of testing parameters, to ensure the accuracy and reliability of the test results.

Again, in terms of test result analysis, it is necessary to conduct comprehensive analysis and evaluation of the test data. Usually, the seismic performance of aluminum veneer is judged based on the size and trend of the test results to determine whether it meets the requirements. If the test results do not meet the specified requirements, it is necessary to readjust the design and installation plan of the aluminum veneer to improve its seismic performance.

After testing, quality inspection and acceptance work need to be carried out to ensure that the quality of the selected materials meets their requirements and standards. In this process, it is necessary to pay attention to factors such as the dimensional accuracy, surface smoothness, and color uniformity of the aluminum veneer to ensure that the quality and effect of the aluminum veneer meet one's own requirements and standards.

The seismic performance testing of 1.5mm aluminum veneer is a very important process that requires reasonable selection and processing based on specific building requirements. In practical applications, attention should be paid to the quality and effectiveness of the selected materials to ensure better decorative and usage effects.

Customer service QQ

Customer service QQ