Industry information

Company News

- Aluminum veneer: a shining pearl in architecture, both environmentally friendly and fashionable

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum curtain wall: the beauty of architecture, the light of technology

- Aluminum veneer: the fashionable "coat" of modern architecture

Industry dynamics

- Design and Construction Points of Aluminum Square Ceiling for Curtain Wall

- The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

- International market for stylish aluminum veneer

- The counterattack of aluminum honeycomb panel: lightweight and durable, the new favorite of future building materials

- Aluminum veneer: the new darling of modern architecture. How much do you know about it?

Frequently asked questions

- What are the characteristics of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

- What is the market demand for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Application and Innovation of Punching Process for 2.0mm Aluminum Veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 21, 2025 18:48:03

- Click:0

2.0mm aluminum veneer is a commonly used building decoration material, and the application and innovation of its punching process have brought more new ideas and solutions to the building decoration industry. The following will provide a detailed introduction to the application and innovation of the 2.0mm aluminum veneer punching process.

1、 Application

1. Decorative

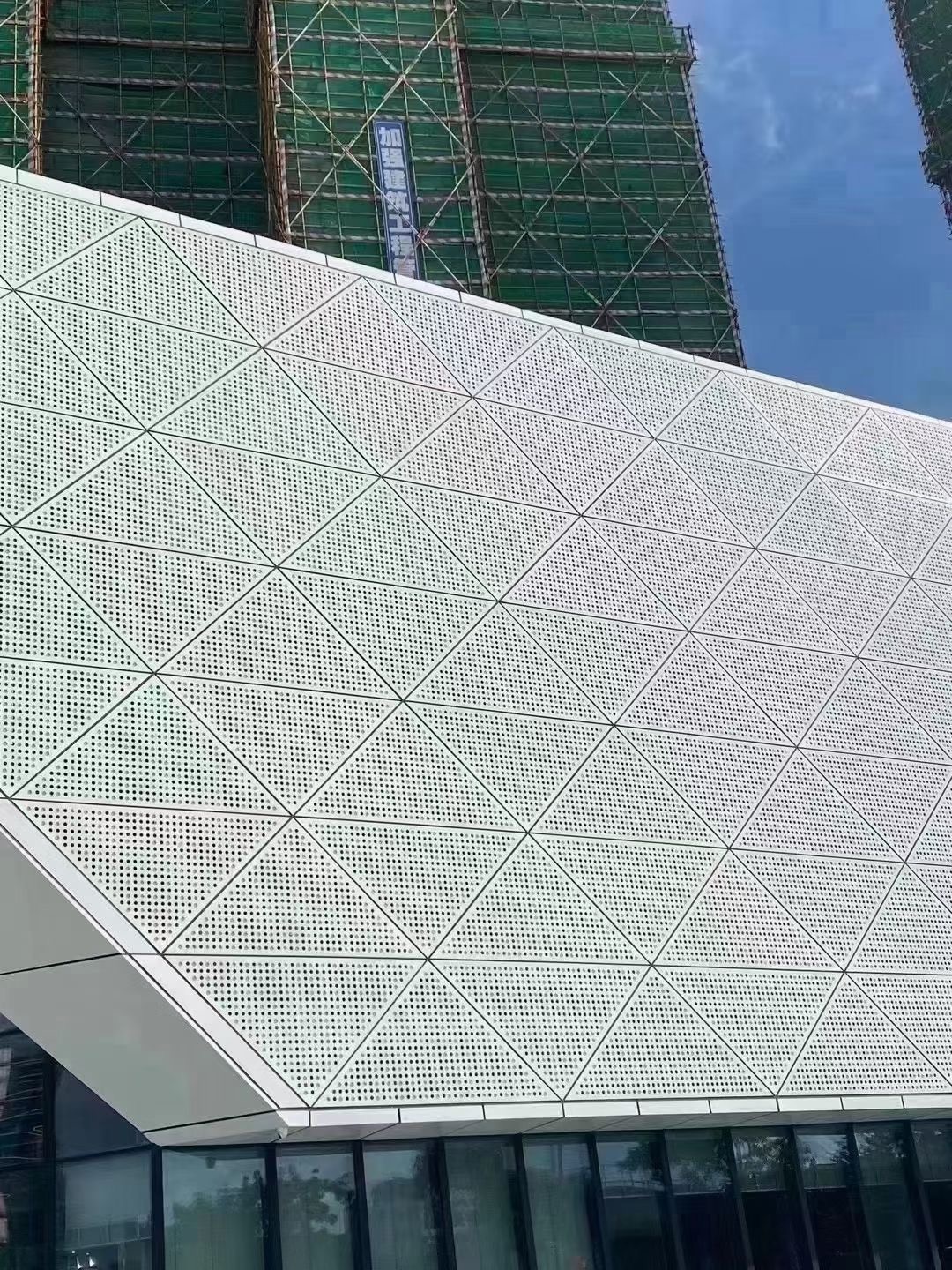

The punching process of 2.0mm aluminum veneer can achieve various patterns and shapes, with strong decorative properties. Through reasonable design and manufacturing processes, beautiful, practical, and environmentally friendly perforated aluminum veneers can be produced, adding artistic atmosphere to buildings while improving their functionality and comfort.

2. Sound insulation effect

The punching process of 2.0mm aluminum veneer can achieve good sound insulation effect and effectively reduce noise pollution. Compared to other building materials, 2.0mm aluminum veneer is lighter, easier to handle and install, and can reduce the weight of buildings and improve their safety. Through reasonable design and manufacturing processes, beautiful, practical, and environmentally friendly soundproof aluminum veneers can be produced, adding artistic atmosphere to indoor spaces while improving indoor comfort and safety.

3. Ventilation effect

The punching process of 2.0mm aluminum veneer can achieve good ventilation effect, effectively increase indoor air circulation and improve indoor air quality. Compared to other building materials, 2.0mm aluminum veneer is lighter, easier to handle and install, can save manpower and material resources, shorten the construction period, and improve construction efficiency. Through reasonable design and manufacturing processes, beautiful, practical, and environmentally friendly ventilated aluminum veneers can be produced, adding artistic atmosphere to indoor spaces while improving indoor comfort and air quality.

2、 Innovation

1. CNC punching technology

Numerical control punching technology is a new type of punching process that can achieve high-precision punching effects. By controlling the running trajectory and punching depth of the punching machine through a computer, more precise and beautiful punched aluminum veneers can be produced. Compared to traditional manual punching technology, CNC punching technology has higher precision and efficiency, and can meet the needs and personalized requirements of more different customers.

2. Laser punching technology

Laser punching technology is a new high-tech punching process that can achieve very precise punching effects. By precise cutting and punching of aluminum veneers with laser beams, more exquisite and unique punched aluminum veneers can be produced. Compared to traditional manual punching techniques, laser punching technology has higher precision and efficiency, and can meet higher end customer needs and personalized requirements.

3、 Summary

The punching process of 2.0mm aluminum veneer has broad application prospects and innovative potential. In the future, we believe that the punching process of 2.0mm aluminum veneer will be more widely applied and developed, bringing more new ideas and solutions to the building decoration industry.

Customer service QQ

Customer service QQ