Industry information

Company News

- Aluminum veneer, creating a new fashionable "metal garment" for modern architecture

- The secret of honeycomb aluminum plate: the perfect combination of lightness and strength

- The secret of aluminum honeycomb panel: the perfect combination of lightweight and sturdy

- The Secret of Honeycomb Aluminum Plate: A Legend of Lightweight and High Strength Modern Materials

- Aluminum honeycomb panel: the technological power behind its lightweight design

Industry dynamics

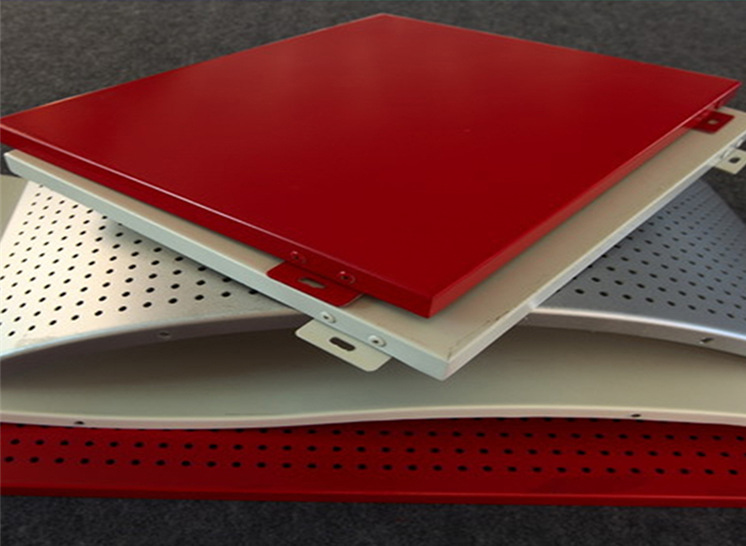

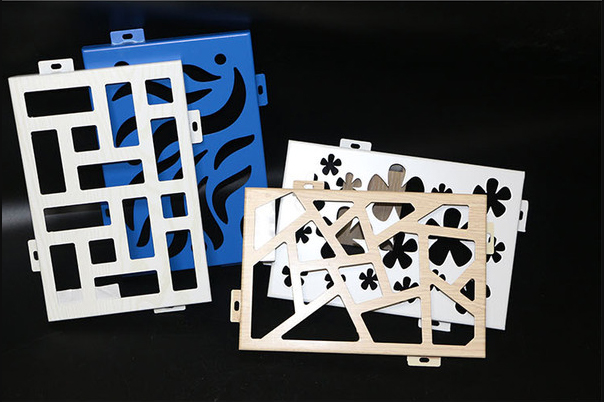

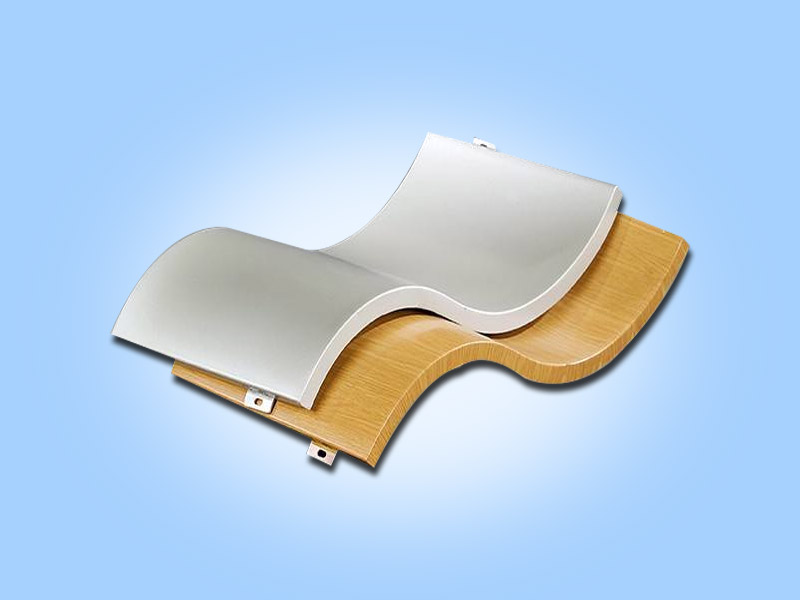

- Customized performance characteristics of aluminum veneer

- What is the fire rating of aluminum veneer?

- Aluminum veneer provides excellent sound insulation for buildings

- Honeycomb aluminum plate: a secret weapon as light as a feather and as solid as a rock

- Aluminum veneer: the fashionable outerwear of modern architecture

Frequently asked questions

- What is the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Sharing of construction techniques for aluminum veneer in engineering walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 16, 2025 19:23:33

- Click:0

Aluminum veneer for engineering walls is a commonly used building material, which has been widely used in the construction industry due to its advantages of lightweight, high strength, and corrosion resistance. To ensure the construction quality and effectiveness of aluminum veneer for engineering walls, it is necessary to master some construction techniques. This article will share some construction techniques for aluminum veneer in engineering walls, hoping to be helpful to everyone.

1、 Wall treatment

Before installing the aluminum veneer on the engineering wall, it is necessary to treat the wall surface. Specifically, it is necessary to first clean the dust, oil stains, and other debris on the wall surface, and then use sandpaper to polish the wall surface to make it smooth and even. If there are cracks or uneven areas on the wall, it is necessary to fill the gaps with sealant and sand them flat with sandpaper.

2、 Measurement and cutting

Before installing the aluminum veneer on the engineering wall, it is necessary to measure and cut it first. It is necessary to use a level and ruler to measure the wall and determine the size and position of the aluminum veneer. Cut the aluminum veneer according to the measurement results to ensure its accurate size.

3、 Install the keel

Installing the keel is one of the key steps in installing aluminum veneer panels for engineering walls. A keel needs to be installed on the wall to support the aluminum veneer. The installation of the keel should pay attention to the following points: the position of the keel should be accurate and correct; The height of the keel should be perpendicular to the wall; The number of dragon bones should be determined based on the actual situation.

4、 Install aluminum veneer

When installing aluminum veneer, it is necessary to fix the keel on the wall and then place the aluminum veneer on the keel. During the installation process, the following points should be noted: the position of the aluminum veneer should be accurate and correct; The angle of the aluminum veneer should be perpendicular to the keel; The edges of aluminum veneer should be sealed with sealing strips to prevent rainwater from seeping in.

5、 Punching and fixing screws

After installing the aluminum veneer, it is necessary to drill holes on it and fix screws. The drilling position should be accurate and precise; The size of the hole should match the screw; The number of screws should be sufficient to ensure that the aluminum veneer is firmly fixed to the wall.

6、 Closing work

After installing the aluminum veneer on the engineering wall, some finishing work is required. Need to clean the dust and garbage on the wall; Seal the edges of the aluminum veneer with sealing tape; Check if the aluminum veneer is securely fixed to the wall, and adjust it promptly if there are any issues.

The above is the construction technique of aluminum veneer for engineering walls shared this time. By mastering these techniques, the construction quality and effectiveness of aluminum veneer for engineering walls can be ensured. Of course, these are just some basic techniques that need to be adjusted and improved according to specific situations during actual construction.

Customer service QQ

Customer service QQ