Industry information

Company News

- Aluminum curtain wall, the fashionable coat of modern architecture

- The wonderful world of aluminum honeycomb panels: the new favorite of lightweight and sturdy panels

- Aluminum honeycomb panel: the secret power behind lightness

- Aluminum veneer: not only a building material, but also the soul of architecture

- Aluminum Curtain Wall: Creating an Artistic Window for Modern Architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Aluminum ceiling new trend: the fashionable choice for modern architecture

- The Charm of Aluminum Honeycomb Panels: The Secret of Strength Hidden in Lightness

- Aluminum curtain wall: the fashionable coat of modern architecture

Frequently asked questions

- What are the main uses of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the size specifications of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 20:12:01

- Click:0

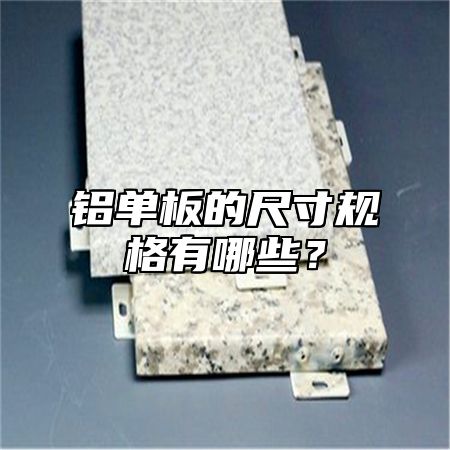

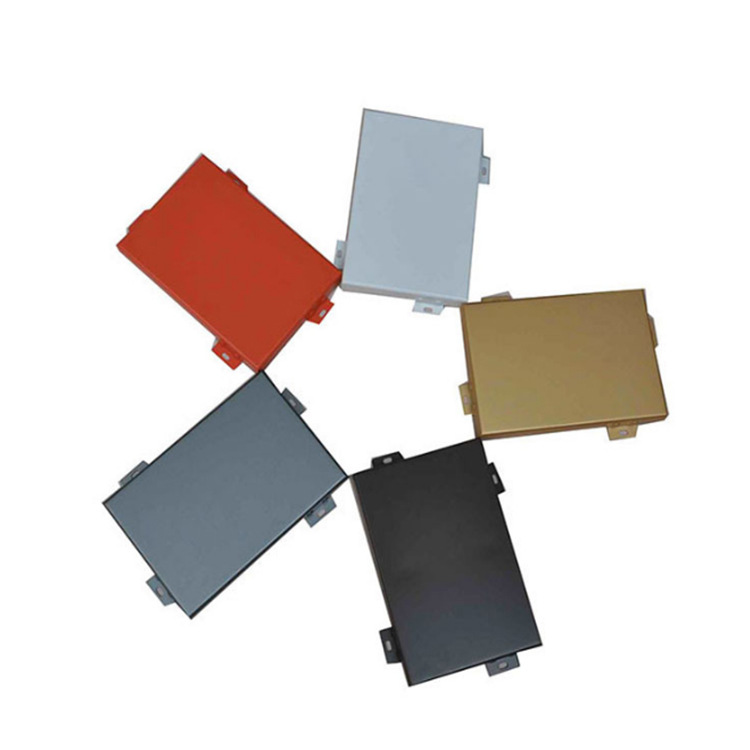

Aluminum veneer is a material widely used in construction, decoration and other fields, and its size specifications are one of the important factors affecting its usage effect and installation method. The following will provide a detailed introduction to the size specifications and characteristics of aluminum veneer.

1. Common size specifications

There are many sizes and specifications for aluminum veneer, and the common ones are as follows:

(1) Ordinary aluminum veneer with a thickness of 1.5mm-3mm, generally with a length and width within 2000mm;

(2) Medium thick aluminum veneer with a thickness of 4mm-18mm, generally ranging in length and width from 2000mm to 3000mm;

(3) Ultra thick aluminum veneer with a thickness of 18mm or more generally has a length and width of 3000mm or more.

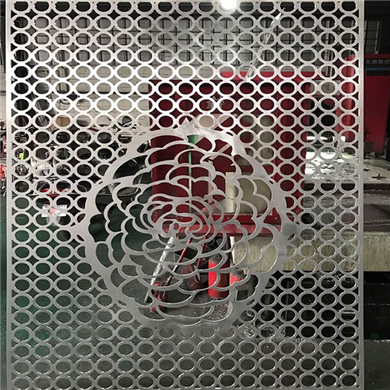

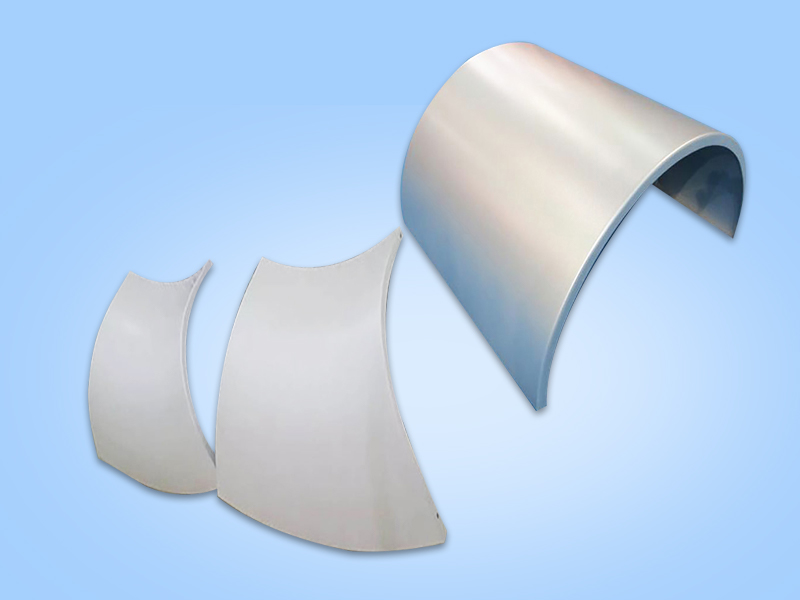

There are also some special specifications of aluminum veneer, such as curved aluminum veneer, irregular aluminum veneer, etc., which can be customized and produced according to customer needs.

1. Principle of size selection

When choosing the size specifications of aluminum veneer, the following principles need to be considered:

(1) Select appropriate size specifications based on actual needs to meet design requirements and usage scenarios;

(2) Considering the convenience of transportation and installation, try to choose shorter lengths and widths to reduce transportation costs and installation difficulties;

(3) Considering the strength and stability of aluminum veneer, it is advisable to choose a thicker thickness to increase its load-bearing capacity and service life.

1. Size calculation method

After determining the size specifications of the aluminum veneer, it is necessary to perform size calculations to ensure that it can be installed correctly on the building. Generally speaking, the size calculation method for aluminum veneer includes the following steps:

(1) Determine the length, width, thickness and other parameters of the aluminum veneer according to the design drawings;

(2) Calculate the required number and spacing of keels based on the structure and load conditions of the building;

(3) Calculate the position and spacing of the aluminum veneer based on the position and quantity of the keel;

(4) Produce and process according to the calculation results to ensure that the size and position of the aluminum veneer meet the design requirements.

The size specifications of aluminum veneer are one of the important factors affecting its usage effect and installation method. Enterprises should choose appropriate size specifications based on actual situations and strictly follow the size calculation method for production and processing to ensure the quality and effectiveness of products.

Customer service QQ

Customer service QQ