Corporate News

Company News

- Aluminum veneer customization, creating your exclusive art space

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer, the 'hidden hero' of modern architecture?

- The secret of aluminum honeycomb panel: the perfect combination of lightness and sturdiness

- Aluminum Curtain Wall: A Fashionable Choice in Modern Architecture

Industry dynamics

- The charm of honeycomb aluminum plate: lightness contains strength

- Aluminum Curtain Wall: The Silver Coat of Modern Architecture

- Aluminum honeycomb panel: a perfect combination of lightness and strength

- The charm of aluminum honeycomb panels: lightweight and high-strength, the new darling of future architecture

- What impact does the weight of aluminum veneer have on installation?

Frequently asked questions

- How long is the service life of aluminum veneer?

- What are the main uses of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What are the characteristics of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The wonderful world of honeycomb aluminum plate: as light as a feather, as solid as a rock!

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-09 23:22:14

- Click:0

Friends, today let's talk about something that sounds a bit mysterious - honeycomb aluminum sheet. You may think that this name is a bit fancy, but in fact, it is right beside us, silently playing its magical role.

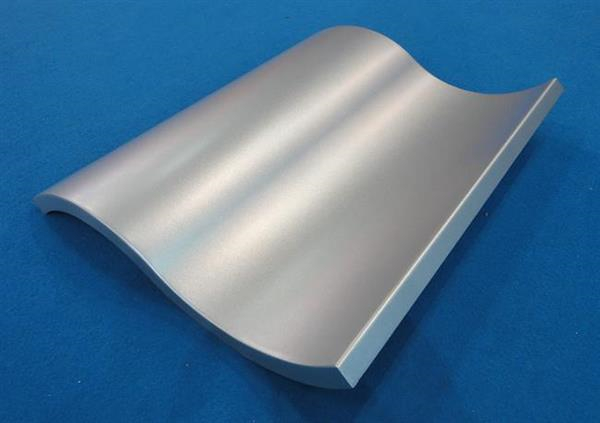

Imagine a honeycomb with those small hexagonal holes, doesn't it remind you of something? By the way, the honeycomb structure makes them both lightweight and sturdy. Honeycomb aluminum plate is made by borrowing this structure and using aluminum alloy. It sounds a bit like high-tech materials from science fiction novels, but in fact, it is all around us and widely used in fields such as architecture, aviation, and automobiles.

Let's talk about its lightness. The weight of honeycomb aluminum plate is only about 1/10 of the same volume of steel, it is simply "as light as a feather". Imagine if you were holding a honeycomb aluminum plate in your hand, you would feel that it weighs almost nothing. This lightweight feature makes it shine in the aerospace industry, as the aircraft's fuselage and wings can be made of honeycomb aluminum panels to reduce weight and improve fuel efficiency.

Let's talk about its durability again. Although honeycomb aluminum sheet is lightweight, its strength is astonishing. Those honeycomb shaped holes not only reduce weight, but also increase the material's bending and compression resistance. Just like the hexagonal structure of a honeycomb, each small hole is a support point, allowing the honeycomb aluminum plate to withstand enormous pressure. Don't be fooled by its lightness, the honeycomb aluminum plate is as solid as a rock!

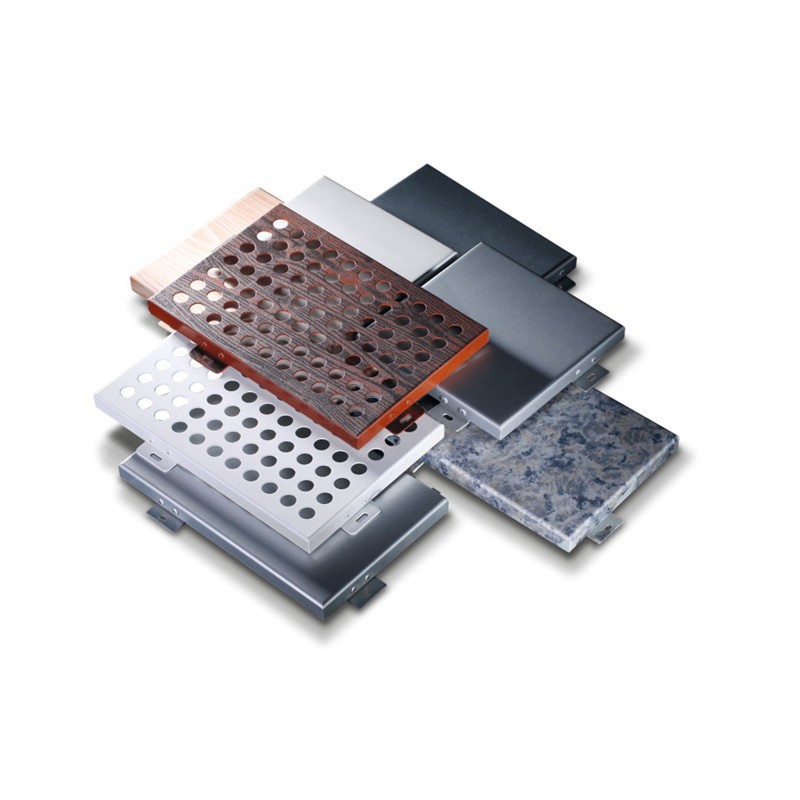

Where exactly does it apply? Let's talk about the construction industry first. Honeycomb aluminum panels can be made into wall panels, ceilings, roof panels, etc., which are both beautiful and practical. It has good sound insulation and thermal insulation performance, and can also play a certain role in fire prevention. Believe it or not, many high-end commercial buildings and residential communities are decorated with honeycomb aluminum panels.

In the aerospace industry, honeycomb aluminum panels are like fish in water. The fuselage, wings, tail and other parts of an airplane cannot do without honeycomb aluminum panels. It can not only reduce the weight of the aircraft, improve fuel efficiency, but also increase the stability and safety of the aircraft.

The automotive industry is also not willing to fall behind, and the application of honeycomb aluminum panels in automobiles is becoming increasingly widespread. Honeycomb aluminum panels can be used to reduce weight and improve fuel economy in parts such as the car body, seats, and dashboard. Honeycomb aluminum plate has good impact resistance and can protect the safety of passengers inside the car.

How is honeycomb aluminum plate manufactured? This is thanks to advanced manufacturing techniques. Punch the aluminum alloy plate into the desired shape, then perform surface treatment, and finally stick the honeycomb paper on the aluminum alloy plate, thus forming the honeycomb aluminum plate. The entire production process is strictly controlled to ensure the quality of honeycomb aluminum plates.

Having said so much, do you have a deeper understanding of honeycomb aluminum panels? There are many magical materials in life, such as honeycomb aluminum panels, which silently provide convenience for our lives. Let's look forward to the future together and explore the charm of more technology!

Personal experience sharing: A few years ago, I interned in a maintenance workshop of an airline company. At that time, I first came into contact with honeycomb aluminum panels. Looking at those lightweight aluminum alloy plates, I was amazed by their magic. Later, I learned about the widespread application of honeycomb aluminum panels in the aerospace industry, and couldn't help but feel proud of China's technological development.

Honeycomb aluminum plate, this magical material, has witnessed the power of technology. It is both lightweight and sturdy, bringing many conveniences to our lives. Let's look forward to more innovative materials like honeycomb aluminum panels in the future, creating a better life for us!

Customer service QQ

Customer service QQ